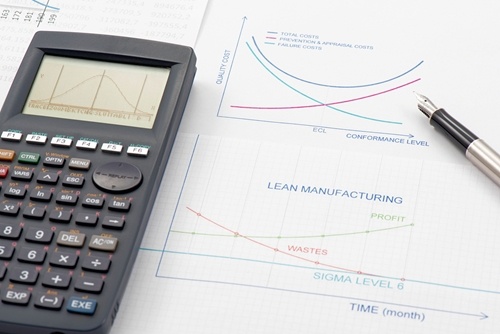

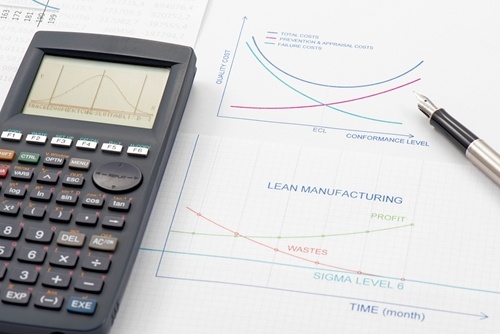

The Great Recession of the early 2000s was a period when many businesses were recognizing the need to eliminate waste if they want to keep up with changing global economic demands. The manufacturing sector went through a major shift during that time as lean principles became mainstream.

As more businesses expected manufacturers to reduce product costs, those manufacturers looked to warehouse and supply chain to keep costs down. Why have a human do work that a machine can do? That person is more valuable focusing on skilled jobs that require personal input. Why settle for a culture of complacency? Drive continual improvement to sustain consistent, iterative growth. These lean principles – avoiding waste and fostering ongoing improvements – have come to define the manufacturing sector. It is a lesson that is starting to reach the retail sector.

Lean Principles in Retail

The progress that has taken place in the manufacturing sector in recent years serves as a model for how retailers can respond to the growing demands created by the e-commerce industry, Supply & Demand Chain Executive reported. Taking the lean principles used in manufacturing and applying them to retail can drive efficiency across the entire supply chain regardless of the goods being sold. Putting an emphasis on waste reduction in the supply chain can be invaluable in retail, but doing so depends on careful analysis of the supply chain. In fact, the report pointed to a need to look holistically at the supply chain as the first step to applying lean principles in retail. This sentiment was echoed in an IDC study.

In its recent MarketScape study assessing the retail warehouse management system sector, IDC explained that knowing the full complexity of the supply chain is critical for retailers when selecting a warehouse automation software. Other key considerations include developing internal champions and identifying opportunities for value in the supplementary solutions associated with a WMS platform.

This advice is all well and good, but what does it really mean for retailers trying to go lean? There’s a great deal to think about through this process, and organizations must take a particularly intentional approach to putting new solutions in place. Follow these five steps to simplify the process of using lean principles in the retail supply chain:

Step 1: Know Yourself

As mentioned in the S&DCE and IDC reports, it is vital that organizations carefully evaluate their supply chain operations before they dive head first into a lean transition. What does that process actually look like? Here are a few things to consider:

- What geographic issues impact costs and logistics within the supply chain?

- How are you managing orders with vendors?

- How much budget space do you have relative to the number of resupply orders that go out?

- Do you have longstanding relationships with any supply vendors that will make it easier or more difficult to enact changes?

- What inventory levels must be maintained to ensure smooth operations?

- Where do goods need to be stored to optimize efficiency across the supply chain?

These are just a few big-picture questions that should be considered. Ultimately, every business is a little different and organizations must look at the unique factors that will impact their ability to control the supply chain. Because of this, it is vital to first understand all of the nuances of the supply ecosystem before looking into how companies can eliminate waste.

Step 2: Ask Your Employees

Many businesses initiate major changes in core parts of the company, such as the supply chain, at the executive or director levels. It makes sense – these employees have the full visibility into actual operations data needed to make these key decisions. Furthermore, they tend to be the people with the experience and authorization to actually drive change. However, all data comes with a context. It can be difficult to pin down that context unless leaders have a close connection with the people actually getting the job done.

As companies work to get to know themselves better to enact lean operations, they must create internal transparency and get employees involved in the process. Balancing the voices involved in questions regarding change can ensure organizations don’t have any blind spots as they make key decisions.

Step 3: Initiate Cultural Change

Adjusting operations requires a great deal of disruption as employees must adapt to new expectations. This kind of stress can be difficult for workers to deal with if they don’t understand the underlying decisions and issues driving the change. Because of this, major adjustments to the supply chain must go hand-in-hand with cultural shifts that help employees get a sense of what is happening at the business. Clear communication, leading through example and similar efforts are necessary in ensuring a new culture takes hold.

Step 4: Train Workers

You’ve planned for a lean supply chain. You’ve changed your culture and you’re ready to put a new WMS in place. You aren’t finished yet, though. Training employees is critical to ensure users don’t get overwhelmed by all of the new processes, procedures and technologies that come with this disruption. Training is an integral final step in rolling out a major new technology or strategy. Applying lean principles in the retail supply chain touches on both tech and tactics, so companies must prepare their workers accordingly.

Step 5: Don’t Get Complacent

Lean methodologies are built around the idea of continuous improvement. Retailers hoping to embrace lean can’t approach the transition as a one-off project. Instead, lean is a way of working. Once you have a new WMS system and supporting procedures in place, it is time to restart the cycle and go back to self-analysis. Take time to let the system settle in, but don’t rest on your laurels. Begin analyzing areas of strength and weakness quickly and get to work improving them.

The manufacturing sector was revitalized by a move toward lean operations. As retailers face new challenges, they can apply lean principles themselves to optimize the supply chain and drive consistent, sustainable growth.