What Is Supply Chain Visibility? Your Complete Guide

- Inventory/Warehouse

- Supply Chain

Imagine having a real-time view of every product, component, and raw material moving through your supply chain. That’s the power of supply chain visibility (SCV)—a critical capability that allows businesses to track, analyze, and optimize their operations with unparalleled accuracy.

In a world where supply chains can change overnight, SCV is more than just an efficiency booster—it’s a strategic necessity. From reducing costs to improving customer satisfaction, businesses that harness real-time data and predictive analytics can respond swiftly to disruptions, streamline inventory management, and enhance overall supply chain performance.

This guide will explain supply chain visibility, why it matters, and how to implement it effectively. Whether you’re looking to improve demand forecasting, optimize logistics, or strengthen supplier collaboration, you’ll discover practical strategies to build a smarter, more resilient supply chain.

Let’s explore how real-time insights can transform your operations and help you stay ahead in an increasingly complex marketplace.

What Is Supply Chain Visibility?

Supply chain visibility is the ability to track and monitor products, materials, and information throughout your entire supply chain, from sourcing raw materials to final delivery. It provides real-time data on the movement, location, and status of goods, as well as the processes involved in their production and logistics.

With supply chain visibility, you gain insights into:

- Inventory levels

- Production processes

- Transportation routes

- Distribution networks

- Supplier performance

- Demand patterns

Go deeper: Did you know 74% of companies lack sufficient inventory automation? Download the supply chain guide to learn how total inventory tracking can transform your business.

DOWNLOAD NOW »A diverse supplier network is essential for managing complexities, ensuring customer satisfaction, and maintaining competitiveness in a global supply chain.

By implementing supply chain visibility solutions, you’re equipping yourself to handle the complexities of modern global supply chains. It’s like having a GPS for your business, helping you navigate challenges and find the best route to success.

Why Supply Chain Visibility Matters

Supply chain visibility is the key to staying competitive, meeting customer expectations, and keeping your operations running smoothly.

Here’s why it matters:

- Operational Efficiency: Real-time data helps you identify and fix inefficiencies quickly. It’s like having a constant improvement team working 24/7 on your supply chain.

- Risk Management: Spot potential issues before they escalate. You’ll be able to pivot and adapt, keeping your supply chain resilient in the face of challenges.

- Customer Satisfaction: Accurate delivery estimates and improved order fulfillment mean happier customers, who often become loyal customers.

- Inventory Optimization: Say goodbye to stockouts and excess inventory. Precise tracking helps you maintain just the right amount of stock.

- Smarter Decision Making: With comprehensive insights at your fingertips, you can make strategic decisions based on solid data.

- Stronger Partnerships: Regular performance monitoring fosters better collaboration with suppliers and partners.

- Simplified Complexity: Get a clear overview of all supply chain processes, making managing even the most intricate supply networks easier.

- Breaking Down Silos: Eliminate information barriers between departments and partners, promoting a more cohesive operation.

- Improved Forecasting: Analyze historical data and market trends to predict demand more accurately.

- Regulatory Compliance: Easily track and document requirements across your supply chain, reducing compliance headaches.

- Cost Optimization: Identify areas where you spend unnecessarily and streamline your operations.

- Increased Agility: Respond quickly to market changes and unexpected disruptions, keeping you ahead of the curve.

How Supply Chain Visibility Works

Supply chain visibility isn’t magic – it’s a combination of smart technologies, data integration, and collaboration. Let’s break it down:

Types of Visibility

There are different flavors of SCV, each giving you insights into specific areas of your operation:

- Inventory Visibility: Know what’s in stock, where it is, and how fast it’s moving.

- Order Visibility: Track orders from the moment they’re placed until they reach the customer.

- Shipment Visibility: Get real-time updates on where your goods are in transit.

- Production Visibility: Peek into your manufacturing processes to spot inefficiencies.

- Supplier Visibility: Monitor your suppliers’ performance and if they’re meeting your standards.

- Demand Visibility: Forecast what your customers will want next.

- Financial Visibility: Keep tabs on costs and transactions across your supply chain.

Each type of visibility contributes to a fuller picture of your supply chain, helping you make better decisions and improve efficiency.

Read about 4 more tips to mitigate supply chain risks.

READ MORE »The Building Blocks of Visibility

To achieve true supply chain visibility, you need a few key components working together:

- Data Collection Systems: This includes IoT devices, RFID tags, sensors, and barcodes that gather information from every corner of your supply chain.

- Data Integration Platforms: Software that pulls all that data together, making sense of the information from various sources.

- Advanced Analytics: AI and machine learning tools that crunch the numbers and spot patterns humans might miss.

- Cloud Solutions: Centralized storage that makes your data accessible anytime, anywhere.

- Communication Networks: Secure channels for sharing real-time data across your organization and with partners.

- Collaboration Tools: Platforms that allow everyone in your supply chain to work together seamlessly.

- Visualization Tools: Dashboards and reports that present complex data in easy-to-understand formats.

These components work together to give you a clear, unified view of your operations. It’s like having a control room where you can monitor and optimize every aspect of your operation, respond quickly to changes, and stay ahead of the competition.

How to Implement Supply Chain Visibility

Ready to bring supply chain visibility to your business? Here are a few high-level steps you can take to get started.

- Set Clear Goals: Define what you want to achieve with supply chain visibility. Are you looking to cut costs, improve customer satisfaction, or both?

- Identify Critical Data Points: Determine the most important information for your business. Focus on collecting data that will drive meaningful insights.

- Standardize Supply Chain Processes: Develop consistent methods for collecting and sharing data across your organization and with partners.

- Foster Collaboration: Get everyone on board – from suppliers to customers. Supply chain visibility works best when all stakeholders are involved.

- Invest in Training: Ensure your team knows how to use new technologies and interpret the data they provide.

- Embrace Continuous Improvement: Use the insights you gain to refine and optimize your processes constantly.

- Build a Transparent Culture: Encourage open communication and data sharing throughout your organization.

While it’s possible to achieve some level of supply chain visibility at any stage of tech maturity, modern supply chain management software makes it much easier.

Tools and Technologies that Enable Supply Chain Visibility

You need a combination of advanced technologies and integrated solutions to achieve true supply chain visibility. Let’s explore the key tools that can transform your supply chain operations.

Mobile Data Collection Systems

Robust data collection systems are at the core of supply chain visibility. These typically include barcode scanners, RFID readers, and mobile devices that capture real-time data across your operations. For instance, RFgen’s mobile data collection solutions use these technologies to track inventory, assets, and shipments in real-time, ensuring accurate and up-to-date information.

Inventory Management Software

Advanced inventory management software is crucial for maintaining the visibility of stock levels across multiple locations. These systems should offer features like cycle counting, real-time updates, and demand forecasting capabilities. Effective solutions, such as those provided by RFgen, help optimize stock levels, reduce carrying costs, and prevent stockouts.

Warehouse Automation Tools

To enhance visibility and efficiency in warehouse operations, automation tools are essential. These can range from pick-to-light systems to automated guided vehicles (AGVs). Implementing such technologies improves accuracy in order fulfillment and provides clearer insights into warehouse processes.

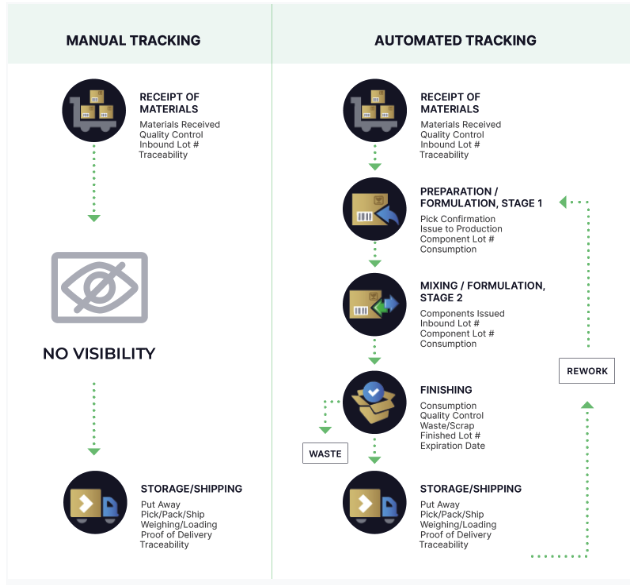

Traceability Solutions

For industries with strict regulatory requirements or those prioritizing quality control, traceability solutions are indispensable. These tools track products throughout the supply chain, from raw materials to finished goods. This capability is particularly important for compliance and quick responses to quality issues or recalls.

ERP Integration Platforms

To avoid data silos and ensure smooth information flow, your visibility tools should integrate seamlessly with your ERP system. Look for solutions that offer pre-built integrations with major ERP platforms like SAP, Oracle, and Microsoft Dynamics. This integration is key to creating a unified view of your operations.

Mobile and Cloud-Based Applications

Access to real-time data on the go is crucial in today’s fast-paced business environment. Mobile apps and cloud-based solutions enable your team to view and act on supply chain data from anywhere, anytime. This mobility enhances collaboration and speeds up decision-making processes.

Analytics and Visualization Tools

Raw data alone isn’t enough; you need tools to transform this data into actionable insights. Advanced analytics platforms and visualization tools help you interpret supply chain data, identify trends, and make data-driven decisions. Look for solutions offering customizable dashboards and reports that can present complex data in an easy-to-understand format.

Internet of Things (IoT) Devices

IoT devices are becoming increasingly important in supply chain visibility. These smart, connected devices can provide real-time data on everything from location and temperature to shock and tilt, offering unprecedented insight into the condition and status of goods in transit.

Combining these tools and technologies allows you to create a comprehensive, real-time view of your entire supply chain. This holistic approach enables you to identify inefficiencies, respond quickly to supply chain disruptions, and make informed decisions that optimize your operations. Whether you’re aiming to improve inventory accuracy, enhance traceability, or streamline warehouse operations, these technologies form the foundation of a visible, efficient, and responsive supply chain.

Maximizing Supply Chain Strategy: A 10-Step Guide

LEARN MORE »Real-World Applications of Supply Chain Visibility Solutions

Let’s look at real-world examples of how companies have leveraged RFgen’s solutions to enhance their supply chain visibility and efficiency and become real supply chain leaders.

Defense Industry: Enhancing Inventory Accuracy and Compliance

A major defense contractor faced challenges with inventory accuracy and compliance with government regulations. By implementing RFgen’s mobile data collection solution integrated with their SAP system, they achieved remarkable results:

- Improved inventory accuracy from 30% to 98%

- Reduced physical inventory time from 3 weeks to just 3 days

- Enhanced compliance with Department of Defense regulations

- Streamlined receiving processes, cutting processing time by 50%

This transformation improved operational efficiency and ensured the company met strict government standards, crucial in the defense sector.

Food and Beverage: Optimizing Distribution and Quality Control

Blue Bell Creameries, a leading ice cream manufacturer, needed to enhance its distribution processes and maintain strict quality control. RFgen’s solution, integrated with Oracle E-Business Suite, delivered significant improvements:

- Achieved 99.9% inventory accuracy

- Implemented real-time visibility of product movement and storage temperatures

- Enhanced traceability for food safety and recall management

- Improved order fulfillment accuracy and speed

These enhancements improved operational efficiency and reinforced Blue Bell’s commitment to product quality and safety, which are critical factors in the food industry.

Transportation: Streamlining Operations and Enhancing Customer Service

A large transportation company sought to improve its operational efficiency and customer service. By implementing RFgen’s mobile solution integrated with JD Edwards, they experienced substantial benefits:

- Reduced data entry errors by 75%

- Improved inventory accuracy to 98%

- Enhanced real-time visibility of shipment status and location

- Streamlined billing processes, reducing invoice time from 2 weeks to 2 days

These improvements led to more efficient operations and significantly enhanced customer experiences through more accurate and timely service.

These case studies demonstrate how companies that achieve supply chain visibility, powered by the right technology solutions, can drive tangible improvements across diverse industries. From enhancing inventory accuracy and compliance in defense to ensuring food safety in manufacturing, and improving customer service in transportation, the benefits of supply chain visibility are clear and substantial.

By implementing similar solutions, businesses can gain real-time insights into their supply chain network operations, improve accuracy and efficiency, ensure compliance with industry regulations, and ultimately deliver better customer value. These success stories underscore the transformative power of supply chain visibility in today’s complex business environment.

Make Supply Chain Visibility a Reality for Your Operations

Supply chain visibility is more than just a buzzword—it’s a powerful tool that can transform your operations. By implementing the right supply chain technology and following best practices, you can achieve end-to-end visibility, from sourcing to delivery.

The benefits are substantial: improved efficiency, better risk management, and more informed decision-making. As global markets evolve, supply chain visibility becomes increasingly crucial for success.

Embracing supply chain visibility isn’t just about keeping up with the competition – it’s about staying ahead. With improved efficiency, better decision-making, and increased agility, you’ll be well-equipped to navigate challenges and seize opportunities in your supply chain.

Remember, the journey to full supply chain visibility is ongoing. Start with the basics, continuously refine your processes, and monitor emerging technologies. Your supply chain—and your bottom line—will thank you.

5 Factors to Consider for Effective Supply Chain Optimization

LEARN MORE »Frequently Asked Questions

1. What is supply chain visibility?

Supply chain visibility is the ability to track and monitor products, materials, and information throughout the supply chain, from sourcing raw materials to final delivery.

2. Why is supply chain visibility important?

Supply chain visibility software enhances transparency, enables businesses to identify bottlenecks, optimize processes, and make informed decisions. It improves operational efficiency, risk management, customer experience, and more.

3. How does supply chain visibility work?

It operates through advanced technologies, data integration, and collaboration among stakeholders. It uses components like data collection systems, integration platforms, analytics tools, and visualization dashboards to create a unified view of the supply chain.

4. How can businesses implement supply chain visibility?

Businesses can implement it by establishing clear objectives, identifying critical data points, developing standardized processes, fostering collaboration, investing in employee training, and leveraging technologies like inventory management software, mobile data collection systems, and traceability.

5. How does IoT contribute to supply chain visibility?

IoT (Internet of Things) devices like sensors, GPS trackers, and RFID tags provide real-time data on inventory levels, shipment locations, and environmental conditions. This data helps businesses make proactive decisions and mitigate risks.

6. What is the role of mobile technology in supply chain visibility?

Mobile devices and applications enable real-time data access, allowing supply chain managers and warehouse staff to track inventory, update orders, and communicate across different locations without being tied to a desktop.

7. What is the connection between supply chain visibility and regulatory compliance?

Supply chain visibility ensures businesses maintain accurate records, track product origins, and comply with industry regulations, reducing the risk of legal issues and penalties.

8. How does supply chain visibility impact customer satisfaction?

Supply chain visibility ensures accurate tracking of inventory, shipments, and order fulfillment, reducing delays and improving delivery accuracy. This leads to better customer experiences, as they receive timely updates and reliable service.