An Intelligent Alternative to WMS: Gaining Real-Time Inventory Visibility Without the Complexity

In a fast-paced warehouse, the need for real-time information extends to every aspect of operations. Inventory management is no exception.

Today’s digital supply chain makes manual inventory control obsolete. Technology solutions step in to help warehouses and production plants streamline materials management and reduce costs.

When first implementing digital warehousing technology, many organizations consider a warehouse management system (WMS). While a WMS platform grants unbelievable levels of control and oversight for warehouse management, these solutions also come with high cost and complexity.

If you’re evaluating WMS for your warehouse, consider looking to alternative solutions that provide similar benefits and the most-needed features for inventory and warehouse management, but without the expense, complexity, or long implementation period.

The Need for Real-time Inventory Visibility

Before we get into WMS alternative solutions, let’s first take a look at why real-time visibility is a must-have for inventory management.

The ability to peek in on stock levels and know they are accurate at any given time is important to prevent inventory management challenges, preserve customer expectations, and create financial efficiency.

More specifically, real-time transparency helps you:

- Find the right inventory in the right place when you need it.

- Reduce overhead costs from overstocking, understocking, and lost sales.

- Deliver accurate, on-time orders for optimal customer service.

- Prevent stoppages on the shop floor from insufficient raw materials or stockouts.

- Ensure proper ordering, inventory planning, and process scalability.

Uncover the Hidden Costs of Manual Warehouse Processes

The Hidden Drawbacks of Best-of-Breed WMS

When leveraging technology to improve warehouse operations, your first instinct may be to search for the best WMS on the market equipped with all the bells and whistles. And while this is understandable, you may wind up investigating solutions that come with high levels of risk.

According to findings by Gartner, 75% of ERP-oriented projects fail. Meanwhile, Clayton Christensen suggests that 70% of digital transformation projects fail, with only 30% of successful projects getting the desired outcome.

With those dismal numbers in mind, why risk implementing a complex project with a high chance of failure? Meanwhile, alternatives exist that don’t fail during the implementation phase and deliver the same benefits (more on that below).

What to Expect When Implementing a New Barcode Solution: A Step-by-Step Guide

Implementing a full WMS solution may come with other unforeseen roadblocks, too, such as:

- High degree of complexity = high degree of implementation failure.

- Significant financial investment = higher level of risk.

- Long rollout period without ROI—up to 24 months.

- Resource requirements for implementation and maintenance.

- Inflexibility of solution, necessitating extra workarounds.

To name a few.

Mobile Barcoding: Core Benefits of an Alternative to WMS

WMS software delivers a lot of benefits, from enabling tracking of warehouse KPIs to streamlining operations. But did you know that you can get all those same benefits without the drawbacks of a heavyweight WMS?

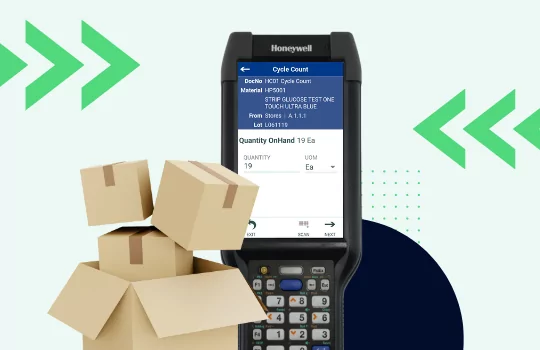

One such alternative is mobile barcoding. Mobile barcoding is an enterprise mobility solution that automates and mobilizes inventory management and warehouse tasks at a fraction of the cost and complexity of WMS.

You get the core benefits without the baggage. Benefits like:

- Real-time visibility

- 99.9% inventory accuracy

- 30-42% more efficiency and productivity

- KPI tracking and improvement

- Reduced overhead spend (labor, carrying costs, etc.)

- Improved customer satisfaction

Other benefits of mobile barcoding include:

- Simplicity. Technology complexity is a difficult barrier. An alternative solution like mobile barcoding prioritizes simplicity, eliminating the need for extra resources or constant debugging.

- Cost-Effectiveness. Traditional WMS can be prohibitively expensive. ROI could be years away, if it ever comes. With mobile barcoding, you can spend a fraction of the cost and get ROI in a matter of months.

- Rapid Time to Market. Whereas WMS platforms can take 1, 2, or even 3 years to implement, mobile barcoding can get to Go Live in just 3-4 months. That means efficiency gains and added value that much sooner.

- Easy to Maintain/Modify. Unlike WMS solutions, mobile barcoding is very easy to maintain due to its high reliability. It’s also very easy to modify, configure, or expand with little effort.

- Flexibility. Due to the complexity of WMS software, you may find yourself re-configuring your operational workflows to conform to the technology. Ideally, it should be the other way around: conforming your software to your business processes—which is how mobile barcoding works.

Features of the WMS Alternative Solution

Barcoding

Barcoding (AIDC) remains a crucial tool in inventory management, automating data collection with perfect accuracy. While many WMS offerings come with barcoding, you don’t need to buy a colossal solution to get that core functionality. Mobile barcoding provides millisecond scanning speeds that update your ERP in real time.

Your Guide to Tracking Your Inventory Anytime, All the Time

Integration with Existing Systems

WMS systems don’t necessarily fully integrate with an ERP. Often, they sit adjacent to your ERP, using their own database and requiring constant reconciliation between the disparate systems. Compare that to mobile barcoding, with standard connectors—and certified integrations—with most major ERP systems, leverage only your ERP database as the single source of truth.

Scalable Solutions

A good WMS alternative should grow with your business. Scalable solutions can adapt to the increasing demands of a growing organization without the need for substantial additional investment. While a WMS can help you scale operations, scaling the WMS solution to multiple sites becomes especially costly—imagine having the same cost and complexity at 32 different locations!

Again, mobile barcoding provides a more scalable solution that’s easier to implement, configure, and expand at much lower cost. For facilities with different operational setups, the difficulty of tailoring the solution is drastically reduced.

Investing in Warehouse Innovation: How to Evaluate ROI for Warehouse Software

Compliance and Security

Meeting regulatory standards and ensuring data security are essential. As an alternative to WMS, mobile barcoding is architected for security and is a principal solution in helping to ensure compliance with government and industry regulations.

Industry 4.0 Integrations

One of the most helpful features of mobile barcoding is its ability to communicate with any data source, hardware or software. Integration with today’s Industry 4.0 devices is no exception. Collect and communicate with IoT and IIoT devices, industrial computers (PLCs), RFID, autonomous vehicles and co-bots, camera hardware, GPS, and various robotics technologies.

Real-world Implementations of Mobile Barcoding

For more than four decades, RFgen Software has been developing and implementing data collection solutions in the supply chain—and countless successful implementations along the way.

Myers Tire Supply: A WMS Alternative Success Story

In one case, just-in-time distributor Myers Tire Supply implemented mobile barcoding with advanced warehousing capabilities to improve end-to-end operational management. Originally seeking a full WMS, their new alternative mobile data collection solution gave them the same functionality they were looking for:

- Directed put-away and sales order pick path optimization

- Managed FIFO inventory valuation and barcoding

- VMI (Vendor Managed Inventory) and consigned inventory management

- Support for vendor receipt via EDI/ASN (Electronic Data Interchange/Advance Ship Notice)

- LMS/TMS integration (Logistic/Transportation Management System)

Myers Tire Supply: JIT Distributor Improves E2E Warehouse Management

Additional WMS Alternative Case Studies

Myers Tire Supply isn’t the only story of an organization implementing a WMS alternative. You may also like:

- Schwing America: Global manufacturer of construction equipment replaces aging software, gains mobile barcoding and advanced warehouse capabilities. Read More »

- Chateau Ste. Michelle Winery: Award-winning Washington winemaker digital transforms warehouse operations with mobile barcoding and license plating. Read More »

- Graphic Packaging: Ubiquitous paper goods manufacturer implements mobile barcoding in 25 sites across North America, scaling operations internationally as well. Read More »

Mobile Barcoding: The Ideal WMS Alternative

If you’re evaluating technologies to transform your warehouse operations, get barcoding, and improve profit margins, then maybe you don’t need a best-of-breed WMS solution. Instead, consider mobile barcoding, a platform-based enterprise mobility solution that can be easily configured to meet exact business needs, now and in the future (i.e., it’s futureproof). Why risk implementation failure and hinder daily operations with excessive complexity when efficiency and ROI are within reach?

By embracing alternatives like mobile barcoding, supply chain companies can position themselves at the forefront of efficiency, customer satisfaction, and financial success in the highly competitive marketplace.