Enhancing ERP Systems for Optimal Inventory Management: A Guide

The Age of Digital Inventory Management

Welcome to the era of the digital revolution. It’s no secret that business landscapes are evolving at the speed of light. Inventory management is no exception.

Long gone are the days when managing inventory was a paper-heavy process. Today, it’s all about digital inventory control. To do that, companies turn to Enterprise Resource Planning (ERP) systems. But, as the saying goes, there’s always room for improvement.

So, how do we bridge the gap between what ERP systems offer and what your business needs for optimal materials management? Let’s dig in and find out.

Bridging the Gap Between ERP and Business Need

ERP systems do a lot. While powerful, they don’t always hit a bullseye for inventory handling, leaving gaps in operational capabilities.

And how can one platform hit a bullseye every time? Supply chain operations are highly complex with countless variables unique to every business. Expecting one software platform to account for every variable is unrealistic.

Therefore, we need to consider other ways to solve those gaps.

Understanding the Gap

Your ERP system only does what it does, much like a puzzle with missing pieces. For instance, it creates digital records but can’t necessarily capture data for those records. To get more out of the ERP, you have to add other technical solutions to your ERP environment—or continue living with inefficiency.

The Role of ERP Systems

ERP systems are like the backbone of an organization, integrating financial data from various departments into a centralized system of record. It’s a strategic necessity for digital transformation.

In supply chain management, the ERP’s role is invaluable in integrating core business functions, including procurement, production, warehousing, sales, and distribution. Meanwhile, the information stored in the ERP database allows for data-driven decision-making and greater operational efficiency.

Data Collection: The Need for Enhancement

Implementing an ERP system is a big step in the right direction. While the ERP helps by enabling digital inventory records, the data that populate those records must be entered manually in some way.

Often, data entry is a mixture of paper tickets, spreadsheets, and hand-keyed information at a fixed workstation. Your ERP’s effectiveness becomes limited to the accuracy of data entered and the timeliness of its entry—if that data gets entered at all.

Although functional in its own way, many warehouse managers may not be aware that there are more cost-effective ways to conduct daily operations. Later on, we’ll discuss technologies that can dramatically transform data collection.

Everything You Need to Know About Mobile Barcoding and Data Collection

Frontline Bottlenecks in Current ERP Systems

Data collection isn’t the only gap that leaves stock control wanting. By default, your ERP system is limited to its location. That means workers must continually scurry around the warehouse in search of items that may or may not exist.

Receiving, put-away, and picking procedures still rely on manual efforts to move inventory. In the meantime, production lines can be left waiting on inputs as pickers struggle to keep up with demand.

Operations outside the four walls become even more challenging. Maintenance techs in the field might not have access to parts or documentation, delaying critical repairs. Delivery trucks can’t update stock records until the end of the day. The list goes on.

And what if you run a successful enterprise business with locations spread across a broad geographic footprint? Reconciling data in your ERP—or multiple ERPs—is next to impossible.

Solving Inventory Management Challenges with Mobile Barcoding for ERP

The Impact of Inefficient Inventory Management

Here the domino effect comes into full force. The operational shortcomings left by your ERP’s limitations can lead to a whole host of issues, such as:

- Cost overruns

- Lost or expired materials

- Work stoppages from bottlenecks

- Subpar quality

- Delayed deliveries

- Unhappy customers

That’s a lot of issues. The question becomes: How do we solve them?

A Step in the Right Direction: Enhancing ERP for Inventory Management

Now that we’ve laid bare the issues, it’s time to roll up our sleeves and start talking about solutions. If you’ve taken the time to browse the dizzying number of technologies that enhance your ERP, then you may be wondering what to choose.

Finding the right inventory-enhancing solutions doesn’t have to be like finding a needle in a haystack. Start by focusing on technologies that address basic challenges, then move on to more advanced capabilities from there. Think walk-crawl-run.

Ideally, you’ll want to find a solution that solves multiple challenges, like data collection and productivity, with the ability to expand to other areas of operation in the future. This gives you the best of both worlds.

Below are a few strategic starting points for enhancing your ERP for the supply chain. Each of these solutions can contribute to unclogging pesky bottlenecks, enhancing visibility, and lowering costs.

Starting with—

Leveraging Automation

Automation isn’t just a technical buzzword. It’s a game-changing transformative strategy for unlocking the full potential of your ERP system.

For the supply chain, automation comes in many forms, from physical automation with robots and carousels to digital process automation achieved through mobile software. AI is quickly emerging as another potential area for automation as well.

However, not every operation needs or has the capability to implement big, expensive automation solutions. For example, an automated storage and retrieval system (AS/RS) that places and retrieves items from storage racks, may be too expensive to implement for the benefits. The same could be said of a warehouse management system (WMS).

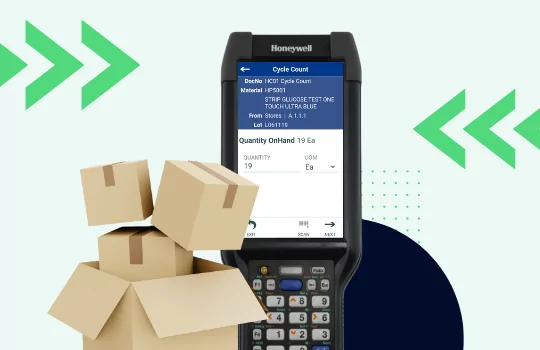

Regardless of your need or budget, virtually any inventory operation can benefit from barcode automation. Scanning barcodes eliminates the need for tedious counts and data entry.

A mobile barcoding solution that seamlessly integrates with your manufacturing ERP is likely the best option. This way, you can leverage automated data collection in collaboration with easy-to-use mobile apps for frontline workers.

An Introduction to ERP Mobility for Supply Chain Pros

Harnessing Data for Forecasting

Data, data, everywhere, but how much of it do we actually use? Leveraging data for accurate forecasting is crucial for any organization looking to optimize.

By analyzing data for future decision-making, you can:

- Understand inventory turns

- Identify chokepoints and slow zones

- Optimize warehouse layouts

- Reduce lead times

- Enhance customer service

However, in order to use data for forecasting, you first need reliable data collection. Otherwise, your data may not be trustworthy. Once again, automated data collection becomes central to achieving this.

Data Analytics: The Secret Ingredient to Efficient Inventory Management

The Future of ERP Systems in Inventory Management

ERP systems continue to evolve. Next-gen ERP platforms like Oracle Fusion Cloud, SAP /4HANA,

Microsoft Dynamics 365, and Deltek ostpoint have become the status quo. Supply chain functionality for these platforms expands continuously.

But what does the future hold?

Expect the following advancements in the near future:

- Advancements in mobile capabilities, specifically around data collection at point-of-work.

- Rising prominence of AI integration and machine learning (ML) to improve demand forecasting.

- Enhanced IoT capabilities in increasing visibility and reducing lead times.

- Increasing use of augmented reality (AR) integration in industrial settings.

With these enhancements, ERP systems will empower organizations to unlock efficiencies that would be otherwise impossible. Greater visibility and profitability are sure to follow.

FAQs: Bridging the Gap in ERP for Inventory Management

What are the most common questions and answers about enhancing ERP inventory control capabilities? Here are your questions, answered—

What is an ERP system in the context of inventory management?

ERP (Enterprise Resource Planning) system in the context of inventory management is a software platform that helps organizations manage and streamline their inventory processes, including purchasing, tracking, manufacturing, and selling goods.

Why is there a gap in ERP systems for inventory management?

The gap often arises because every business is unique, and one-size-fits-all ERP systems may not meet specific inventory management needs. No one platform can solve every problem.

How can I enhance my ERP system for better inventory management?

The most cost-effective ERP enhancement involves mobile data collection, which automates inventory processes and ensures high-quality data for forecasting. Integrating more cutting-edge technologies like IoT, AI, and augmented reality (AR) offer advanced improvements.

What is the role of IoT and AI in enhancing ERP systems for inventory management?

IoT enhances data collection, enabling greater material visibility and efficiency. AI can help in advanced data analysis and prediction for better inventory forecasting. However, AI’s role in the supply chain is evolving quickly.

What are the benefits of enhancing ERP systems for optimal inventory management?

Benefits include improved inventory accuracy, reduced operational costs, much greater efficiency and productivity, faster speeds, increased customer satisfaction, and overall business growth.

Is enhancing my ERP system for inventory management worth the investment?

Absolutely! The initial investment in enhancing your ERP system can yield significant long-term benefits, including increased efficiency, reduced waste, and better decision-making capabilities. Look for a solution that delivers the most benefits with fast ROI, like mobile barcoding.

Bridging the Gap for a Brighter Tomorrow: Your Next Steps

The bottom line is that enhancing your ERP system for optimal inventory management is not just a nice-to-have, it’s a must-have in today’s fast-paced digital world. And while there are any number of solutions out there to help you achieve that, leveraging automation for data collection stands to deliver the most value for the cost. A mobile data collection solution can help you bridge gaps in ERP functionality, driving accuracy, efficiency, quality, and cost reduction across your operation.

Remember: You don’t have to live with inefficiency. Technologies exist that can transform your inventory practices and help your business soar.

If you have questions about what mobile data collection can do for you, don’t hesitate to reach out.