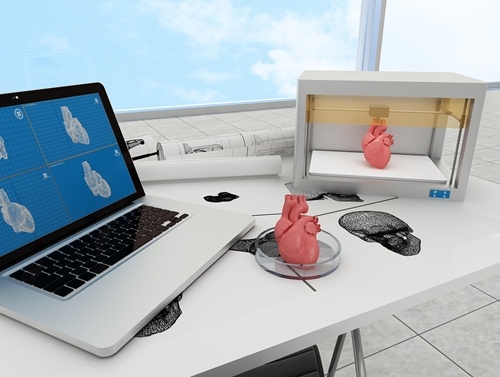

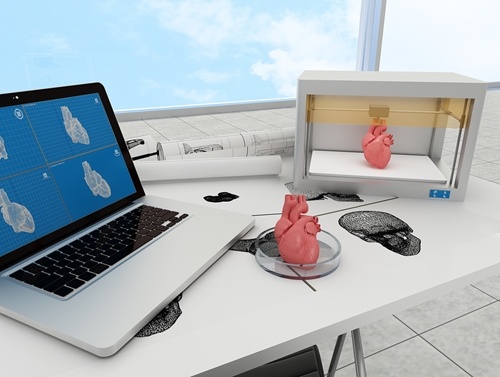

Companies that use 3-D printing – also known as additive manufacturing – create a product one layer at a time. Using detailed virtual designs, often produced by a scan of a physical object, a 3-D printer manufactures an exact copy of the item the data described.

Many companies want to take advantage of this new technology to create products based on very specific requirements. Fortune recently reported Alcoa Aluminum has plans for a $60-million dollar 3-D printing manufacturing center. The company will explore how the additive process could improve designs for aerospace equipment and other materials.

One industry already profiting from the unique advantages of 3-D printing is medical supplies. Doctors and medical company managers like additive manufacturing because it creates specialized solutions for each patient. As the use of ground-breaking technology grows through the medical field, businesses have to adjust their procedures to keep up.

Why The Medical Field is an Early Adopter

Creating an item layer by layer allows the manufacturer to design very specialized products, but the current process is slower than mass production lines. One of the reasons some companies are hesitant to adopt the technology is 3-D printers cannot quite match the speed and cost-efficiency of current procedures.

Medical devices sometimes favor quality much higher than quantity. Doctors use 3-D printers to make replacement parts for the most complicated machine of all: The human body. Science Daily shared the story of a medical team that approached a manufacturer to replace a cancer patient’s rib cage.

The patient had part of his chest plate and rib cage removed while doctors treated tumors. Australian medical company Anatomics created replacement skeletal structures out of titanium. The company used its electron beam metal printer to create a piece that would fit perfectly into the recipient’s body. The artificial ribcage was applied and the patient is recovering.

Many similar stories involve medical procedures using 3-D printer technology to create artificial blood vessels, provide skin grafts and replace missing parts of a human skull. The process works with a variety of materials and can create medical products designed for each particular problem. Scanning processes allow doctors to make 3-D models of internal organs so they can carefully plan surgeries or diagnose difficult problems.

3-D Printing in Mass Production

New technology has sped up the traditional 3-D printing routine. Some products are now mass-produced using additive manufacturing.

In early September 2015, the U.S. Food and Drug Administration approved the first 3-D printed consumer pharmaceutical, according to The Atlantic. Aprecia designed the pill to reduce epileptic seizures. The additive manufacturing process allows the company to apply different ingredients layer by layer. The end product is more porous and potent than previous tableting machines allowed.

As the first pharmaceutical company to 3-D print a drug, Aprecia holds several patents on the innovative technique. The National Law Review said additive manufacturing technology will create many interesting new cases about the information and data that comes from and goes into the processes.

Data Collection in Evolving Industries

Taking a cue from the medical industry, other manufacturers use 3-D printing technologies to create specialized orders for products. The technology keeps improving and as it does, other companies wish to incorporate additive manufacturing into their performance. When companies add new procedures they have to make sure their automated data collection solutions can keep the information accurate and secure.

Products manufactured through 3-D printing are built from digital schematics. A company must load data into a machine and trust the printer to create an accurate representation of the details. Manufacturers that use machine communication need devices to monitor which information goes into a piece of equipment and how the final merchandise matches up to schematics.

Supply & Demand Chain Executive suggested 3-D printed products have the additional risk of security. If an outside party were to break into a company’s digital infrastructure, additive manufacturing data would give them all the information they needed to create counterfeit copies.

A company working with intelligent technology needs a manufacturing and inventory system that is convenient and safe. The RFgen white paper “The Ultimate Supply Chain Mobility Buyer’s Guide” explained how a mobile strategy allows supervisors to check details and working with an experienced software partner provides a company with security. Manufacturers that use mobile data collection solutions gain complete visibility of new procedures and who has access to new ideas.