PART 1: HOW BARCODES STARTED

Barcodes and mobile barcoding are so prevalent today that it may seem like they’ve been around forever. In fact, the opposite is true. Barcodes are a relatively recent invention.

And yet, while the barcode may have not been put into practice until more recently, the idea for it came many years before. Why the delay?

The delayed adoption of the barcode and today’s mobile barcoding technologies are more closely related than they might seem at first glance. To understand the relationship, we need to look at the history of the barcode. That history also explains the current state of the “barcode industry” – especially for manufacturing, distribution, life sciences and wellness, aerospace, and food and beverage companies. There are also insights to be gained into where the industry is going and why there is such a significant focus on mobile barcoding.

For an in-depth look at current industry trends, download our 2022 Digital Inventory Report:

A Brief History of the Barcode

The design for what we would come to know as a barcode started off in the sand of a Florida beach. Oddly enough, the man who got inspiration from several lines in the sand and got people thinking about what would become the barcode was not the one who invented the barcode or universal product code (UPC) that we are all familiar with today.

History is full of twists and turns. The barcode’s history is no different.

Who Invented the Barcode?

Joe Woodland left graduate school in late 1948 and moved to Miami Beach to invent a new way for supermarkets to move people through the stores faster. One day while sitting on the beach he dragged his hand through the sand and while analyzing the lines, he thought of Morse code, and how different lines could have different meanings.

His idea was for a circular or bullseye-shaped barcode. Now, he just needed a way to read it. Heading back to Philadelphia, he started working on a device with a friend, Bernard “Bob” Silver. According to the two of them, the device they created with a 500-watt incandescent bulb worked, but inconsistently. What they needed was a brighter, focused light to read the code and a device to process the information.

In short, they needed a laser to scan and a computer to process. Those would come later.

Fast Forward 20 Years

The laser was invented in 1960 by Theodore Maiman of Hughes Aircraft Company. Computers had been developing, slowly.

Then, in 1972, RCA tested the circular barcode in a Cincinnati Kroger store. While it worked, the circular nature of the barcode didn’t work with all the products sold. For this technology to work, it needed to be universal.

The UPC Barcode, a Pack of Gum, and the Rest is History

Grocery chains recognized the potential to serve customers faster with barcode scanning. They weren’t, however, the only ones to see the benefit of barcodes. Railways had begun to use similar systems in principle earlier, although these applications couldn’t transfer to all industries, like the grocery chains.

Even before Kroger tested the circular barcode, representatives from the grocery trade had set out to settle on a standardized and universal barcode. Several companies got involved, creating proposals. RCA, with its success, felt certain to win. The actual winner was IBM, based on a rectangular code of varying line widths created by George Laurer.

Joe Woodland’s initial lines in the sand ultimately became the standard for what we know today as the UPC code, although the credit for its invention goes to George Laurer, since he was the one to create the actual UPC system.

Thus it was that in June of 1974 a pack of chewing gum was the first product scanned with the modern UPC code.

How did the barcode change the world of inventory management?

It took a while, but once companies saw the benefits of the barcode for inventory management, they never looked back. Tracking inventories became easier and more accurate. Managing inventories could be completed exponentially faster.

Grocery chains, retail stores, and manufacturers of consumer goods recognized the ability to deliver a more streamlined customer experience as well. Today, businesses across all industries rely on barcodes to manage inventory, serve customers, take care of patients and have even made it possible for companies like Amazon to revolutionize how we buy, sell, and ship.

Even as the warehouse barcode system transformed the world of inventory management, mobile barcode scanning continues the evolution with wireless devices and mobile apps.

PART 2: THE BENEFITS OF MOBILE BARCODING FOR TODAY’S ORGANIZATION

Barcodes and barcode scanners have evolved significantly since that first pack of chewing gum was scanned. Today, almost every package contains a barcode, making it one of the most widely used tools for businesses across the product lifecycle.

Barcode scanning has come a long way from the original laser technology. Here’s how the technology has progressed, and how businesses can embrace barcodes to help streamline their operations today.

LEARN MORE: Barcode scanning’s impact on inventory trends »

How barcode scanners have changed over the years

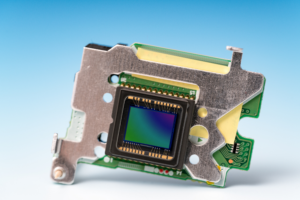

Mobile barcode scanners represent most of the barcode scanners used today. This was made possible by an invention in the 1980s known as the charged-coupled device (CCD) scanner. CCD technology used photocells on a computer chip, which acted as a tiny camera. The result was cheaper than previous laser scanners and paved the way for the invention and rise of RF scanners.

Since then, smartphones have allowed mobile barcode scanning to become easier than ever with advanced image capture and increased portability. Store clerks and warehouse operators now have work-from-anywhere capabilities with Wi-Fi and cellular connectivity. Mobile technology enables real-time information transfer, automating the data collection process for many organizations, including more industrial environments.

From offline mobility to pick routing and continuous operation streams, mobile barcoding has eliminated bottlenecks across multiple areas of business operations as the technology continues to evolve.

The enhanced capabilities of handheld scanners quickly became even more apparent with the rise of COVID-19. The pandemic presented numerous challenges, including social distancing requirements and disrupted supply chain operations. The use of mobile barcoding and automation technology allowed organizations to embrace operational agility and safety to chart a path forward in the midst of uncertainty.

ALSO READ: How Mobile Barcoding Can Help with Supply Chain Issues & Economic Uncertainty »

Why businesses should use mobile barcoding

Our 2022 Digital Inventory Report found that the mobile automation journey ranges from manual systems to fully functional mobile automation, and everything in between. Yet only 16% of participants felt their mobile systems were able to meet current needs.

Embracing mobile barcoding should be the modern standard for all supply chain operations. Perfect data capture is key, as data is the foundation of all sound business decisions. By digitally transforming operations with automated technology, data can flow seamlessly into mission critical systems, allowing leaders to make real-time, informed decisions.

The result is an automated data collection process across the entire organization, removing error, inefficiency, and lack of visibility.

YOU MAY ALSO LIKE: Everything You Need to Know About Mobile Barcoding »

When properly integrated, mobile barcoding can impact several key areas, including:

Shipping & Receiving. Mobile barcoding allows for prompt intake at receiving and processing in shipping, leading to an elevated customer experience. Further, receiving can be done with greater ease at the point of receipt, reducing package movement and time to stocking.

Purchase Order Processing. Mobile barcoding technology can help accurately process receipts with automated data population into ERP and automated purchase order creation when inventory levels reach defined thresholds.

Sales Order Processing. Mobile barcoding allows for real-time scanning of warehouse items and traceability across the warehouse floor. The result? Quality and accuracy in order fulfillment.

Inventory Visibility. Scanning items, parts, and products as they move from the sales or shop floor keeps inventory numbers up to date in real-time.

Cycle Counting. Mobile barcoding automates manual counts throughout inventory zones.

Warehouse Management. Mobile barcoding empowers warehouse managers with visibility into processes and inventory with accurate data and advanced analytics.

Demand Forecasting. Companies experience fewer out-of-stock situations with real-time inventory tracking and predictive reporting that enables managers to better plan.

Fixed Asset Management. Mobile barcoding allows companies to track and manage business assets like technology, equipment, tools, and more, capturing fixed assets anywhere across the enterprise.

Employee Time Management. Mobile barcoding applications can connect with payroll systems, resulting in easy capture of employee time.

Plant Maintenance and Repair (MRO). Service technicians achieve greater efficiency with instant validation of machine and device information as well as an assurance of spare parts supply.

Compliance and Traceability. RF scanners can automate the RF scanners and traceability software for manufacturing can automate the tracing of goods throughout the product lifecycle, from raw materials through production and into inventory and distribution.

Benefits of modern mobile barcoding best practices

The benefits of integrating mobile barcoding into your business today are far-reaching, including:

- Improved data accuracy

- Boosted efficiency and productivity

- Reduction in overhead costs

- Increased customer satisfaction and return rates

- Ability to adapt to new challenges quickly

Ultimately, digital automation technology, like mobile barcoding, can solve a number of problems for organizations. That’s why more than two-thirds of respondents to the Digital Inventory Report are planning to make mobile solutions a significant or fully integrated part of their operations.

But creating new efficiencies takes careful planning and an eye to the future.

PART 3: THE FUTURE OF MOBILE BARCODING

Mobile barcoding has come a long way in changing the business landscape. Across a variety of industries today, mobile and automation technology are leading to increased efficiencies, real-time data capture and transformation in the midst of various challenges.

But what does the future hold for mobile barcoding? And, how can companies embrace operational agility today while leveraging the benefits of mobile barcoding for tomorrow?

READ MORE: Top takeaways from RFgen’s 2022 Digital Inventory Report »

Future Opportunities in Mobile Barcoding

Mobile barcoding provides advanced data collection capabilities by combining barcode scanning with mobile inventory software. Seamless integration with business systems, like an ERP or Industry 4.0 devices, allow for flexibility and speed, leading to growth and profitability.

Here are a few technologies to watch when it comes to mobile barcoding:

QR Codes

2D barcode technology, like QR Codes, has expanded the ability to connect the digital world with physical products. QR codes have become increasingly popular with consumers since COVID-19, resulting in increased awareness of consumer behaviors.

According to the 2022 Digital Inventory Report, over 60% of respondents see surging customer demand as a key obstacle in their operations. Yet only 13% of manufacturers, according to a recent McKinsey study, are able to offer digital solutions to support the desired customer experience.

Innovative businesses have the opportunity to invest in tools like QR codes, expanding their reach to connect consumer to brand. This requires the right hardware and integration when using RF scanners in an industrial setting.

RFID Tags

RFID (radio frequency identification) is quickly growing as a way to help streamline inventory operations. The use of RFID tags can help in asset tracking across the warehouse, as the codes relay data over long distances with ease. This type of inventory automation solution can be used in tandem with barcode scanning.

The use of these tags is one way for organizations to reassess and transform their value chain. 14% of Digital Inventory Report participants are already looking to infuse RFID technology into their automated processes.

Global manufacturers like Toyota use RFID to enhance material visibility during production and transit.

WATCH THE VIDEO: Toyota’s RFID Success Story –

In the face of constant disruption, inventory and supply chain management must be top of mind. According to our Digital Inventory Report, over half of respondents plan to extend the use of mobile devices and related software applications like inventory systems, RFID among them.

The flexibility and connection of mobile barcode scanners and RFID tags represent the need for interconnectivity across multiple devices in order to deliver accurate, up-to-date data to the organization.

SIMILAR: RFID vs Barcode Scanning – What’s the difference? »

Near Field Communication (NFC)

Near Field Communication is the technology that powers mobile payments like Apple Pay or Google Wallet. These types of tags elevate barcode scanning by integrating with smart devices like cell phones and sending detailed information to the consumer.

While primarily used today for consumer payment requests, enterprise organizations of the future could use Near Field Communication to send product information to customers and simply by scanning the packaging.

Digital tools like NFC can help organizations work through common supply chain obstacles and proactively face disruption head on.

In an industrial environment, NFC’s technology can integrate with GPS and other technologies to help track inventory throughout the supply chain to create end-to-end visibility.

Embrace Digital Growth Now

For many, new supply chain technology will be a priority budget item in the coming year, regardless of business size. This investment will not only help companies adapt but also answer ubiquitous operational challenges including a lack of common data platforms, aging legacy equipment, and a shortage in skilled labor.

Companies who do not embrace a digital enterprise mindset stand to fall behind the competition. By incorporating a modern mobile system into daily operations, organizations can find ways to face the future with confidence and embrace digital transformation and profitability.