Lean vs JIT: Understanding the Differences and Choosing the Right Manufacturing Method for Your Business

KEY TAKEAWAYS:

- Just in Time Manufacturing is a business-centric approach focused on efficiency.

- Lean manufacturing emphasizes customer desires.

- Each type prioritizes the elimination of waste, improved efficiencies, and a focus on customer value.

When it comes to producing products, manufacturers have many options for the methodologies they adopt. Just-in-Time (JIT) Manufacturing and Lean Manufacturing are two of the most popular business processes. Although often used as synonyms, they differ significantly.

Just-in-Time Manufacturing focuses on the business side of improving the manufacturing process by lowering costs and reducing lag times.

Lean manufacturing places a focus on customer value across all departments including manufacturing, production, marketing, and distribution.

The main difference between the two comes down to approach. JIT is a business-centric approach focused on efficiency. Lean manufacturing is a customer-centric approach that focuses on using efficiency to add value to the customer.

How do you choose the right manufacturing method for your business? Let’s take a closer look at each to gain a better understanding of their differences.

The 7 Wasteful Manufacturing Practices

The first step in deciding which method to use is understanding the issues they address. There are seven identified wasteful manufacturing practices, more commonly known as the seven wastes:

- Overproduction

- Waiting

- Transportation

- Inappropriate Processing

- Excessive Inventory

- Unnecessary Motion

- Defects

Understanding how your processes will work to alleviate the seven wastes is critical when deciding what philosophy to use.

Lean Manufacturing

Companies that implement lean manufacturing are looking to provide value to customers. Rather than concentrating solely on lowering a supplier’s costs, the emphasis shifts to what the consumer wants, so every step in the process is evaluated in terms of improving the customer experience.

The history of lean manufacturing has roots in the automotive industry. Henry Ford originally set up the auto dealer’s production around the flow of raw materials from beginning to end when the customer drove away in their new car. The process included standardization, reduction of waste, and just-in-time operations. These principles make up much of what lean manufacturing is today.

For instance, the first principle of lean manufacturing is to ensure every step of the process adds value to the customer. This respect for the customer has been found to increase input about items (like production design), leading to a more mutually beneficial outcome.

Eliminating wasteful materials and processes is another essential component. In lean manufacturing, the elimination of waste often means a serious look at inventory management software. For lean manufacturers, products are produced as they are ordered, rather than kept in stock.

Streamlining production is another principle for lean manufacturers. After all, the ultimate goal for lean manufacturing is to improve the production process, resulting in a happier, more satisfied customer.

Inventory software for process vs discrete manufacturing.

Benefits of Lean Manufacturing

Benefits of lean manufacturing methodology include inventory reduction, quality improvement and a more productive labor force. For Hewlett-Packard, the implementation of lean principles resulted in:

- 75% reduction in inventory

- 100% increase in production

- 50% reduction in labor costs

These numbers show how valuable lean manufacturing can be. But it only works with proper implementation. Effective inventory tracking software for production processes is also a must.

Common Implementation Mistakes

Manufacturers must watch for common implementation mistakes, including:

- Lack of strategy. Define objectives, define solvable problems, and set a detailed road map.

- Lack of employee participation. Lean manufacturing only works when employees at all levels are involved in the process.

- Not focusing on the right KPIs. Lean manufacturing focuses on things that drive value to the customer. Manufacturers must ensure they are focusing on these types of metrics and not becoming distracted by the vast amounts of data that exist.

Just-in-Time Manufacturing

The Just-in-Time Manufacturing methodology evaluates every step in the production process with the goal of lowering costs and reducing lag times.

Toyota is generally credited with introducing the JIT concept about 50 years ago in response to an initiative to reduce its inventory and lower operating costs.

JIT reduced Toyota’s lead time on orders by one-third and its production costs by 50%. But JIT’s success didn’t end there. Since its inception, the system proved so successful in other operations that it became a manufacturing staple.

WATCH VIDEO BELOW: A Toyota tracking tech success story –

Benefits of Just-in-Time Manufacturing

When manufacturers embrace JIT methodology, they are hoping to accomplish three things:

- Eliminate waste

- Remove variability

- Improve output

Rather than keep large amounts of components on hand to have when needed, companies place orders more frequently, in smaller quantities.

Ideally, the process flows so that parts arrive “Just In Time” for use (instead of stockpiling), dramatically lowering the volume of inventory in the pipeline. The result? Reduced overall carrying costs.

Common Implementation Mistakes of Just-in-Time Manufacturing

The main issue with JIT methodology is fairly straightforward. The success of this approach relies on precise ordering and stocking between the business and the supplier. If this coordination is off, there is no inventory buffer and production can be delayed.

5 Things to Know About Digital Transformation on the Shop Floor.

Similarities Between Just-in-Time and Lean Manufacturing

Cornerstone to JIT and lean manufacturing methodologies is the need to eliminate waste and improve efficiency. In both philosophies, waste equates to anything that doesn’t add value to the customer.

By removing unnecessary items like excess inventory or the need for production storage, throughput is optimized for faster delivery throughout the production process.

Another similarity between JIT and lean manufacturing involves the priority on customer demand. This begins by understanding what the customer actually wants.

A major challenge faced by manufacturers is creating an accurate, real-time picture of where components are in the manufacturing cycle. With product variety expanding, delivery times shortening, mounting financial pressures and increasing customer demand and expectations, manufacturers must innovate or risk falling out of the competitive race altogether.

JIT and lean both fit in today’s emphasis on agility as well as the notion that supply chains and manufacturing processes must be responsive, flexible, and dynamic. This is critical to providing customer value throughout the manufacturing and inventory process.

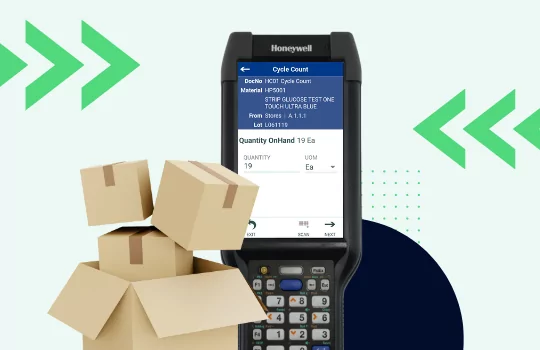

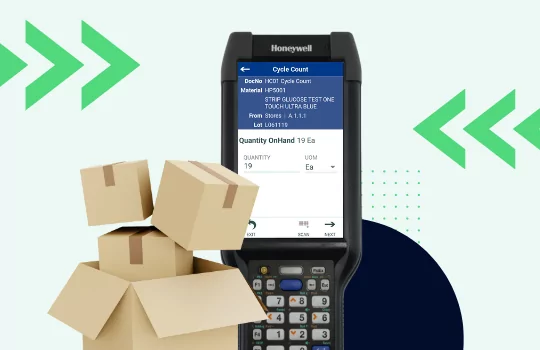

This type of agility and visibility can be achieved with the right solution. Manufacturing data collection solutions can help automate outdated paper processes and workflows. In addition, they can integrate existing business applications, create end-to-end material visibility, and empower real-time access via mobile devices.

Differences Between Just-in-Time and Lean Manufacturing

People Involved

JIT is mainly geared toward employees and partners involved in the manufacturing process—those on the floor as well as moving items through the supply chain.

Unlike JIT, lean manufacturing involves individuals that operate outside of the manufacturing process, such as marketing and customer service groups.

Production Process

Another difference between just-in-time and lean manufacturing processes is how they view the production process.

JIT was designed for processes that delivered one specific item with few variations. Therefore, the manufacturing processes and employee skill sets tend to be more rigid.

Lean offers more flexibility, emphasizing the production of larger or smaller amounts depending on fluctuating market needs. Consequently, manufacturing equipment needs to be flexible enough, so companies do not have to invest in specialized devices every time they want to launch a new product.

Also, employees must have a comprehensive view of the organization. Whereas shop floor workers only interact with factory equipment and workers, lean employees collaborate with individuals, marketing managers, and other positions inside and outside the plant walls.

Approach

Just-in-time manufacturing is more focused on specific aspects of production, namely inventory.

Lean manufacturing is much more comprehensive and holistic. With lean manufacturing, a supplier examines its manufacturing processes in search of ways to lengthen the product lifetime. For instance, they select a higher cost, longer-lasting element to make the product and meet those customer expectations.

5 things you need to know about digital transformation.

Can lean and JIT be used together in manufacturing?

While JIT and lean manufacturing are different, manufacturers do not need to choose one over the other. JIT, while it can be used on its own, is often a part of lean methodology in manufacturing processes.

How to move forward with manufacturing methods

JIT and lean are two management approaches that help organizations evaluate and improve their operations.

Regardless of whether JIT or lean manufacturing works best for a business, embracing automation from the shop floor to the warehouse is important to move forward.

Exploring which manufacturing methodology is right for your company, allows you to review your full supply chain model, outline key success factors, and look to new strategies to help distinguish your business from the competition.